Well we're gonna cover a few items on rigging inspection we're going to start with synthetic web slings and I've got a one inch one ply I and I sling here notice we'll be looking at information that is contained on the tag that needs to be there manufacturer working load limit type of material rated capacities and based on the hitch type etc so in the stock code number for the sling types which are replaceable when necessary and very quickly on the inspection once we've satisfied that all the markings are there appropriately we I start at the far end right up here at the I and I use my hands and fingers to really figure do we have cutting and crushing to add hard plastic surfaces that might indicate melting and charring that may be yeah don't discolor the webbing very much but so I'll work from the I go down both sides open the throat up take a look inside the throat any broken stitching I'll be looking for that or any damaged cuts crushing pinching broken torn snag yarns and fibers all the face front and back and then I'll work my weight right down the slain quickly rotate inspect sweep with my eyes left and right back and forth come down look at the end of the splice I'm not losing any stitching there roll roll continue on to the next splice and work my way right back up to the other eye so I'll open that eye up feel up underneath and see if I can feel any damage any crushed areas cuts or heat damaged etc or any chemical damage potentially and look in the throat so that sling should be in good shape ready to use ready to go so we...

Award-winning PDF software

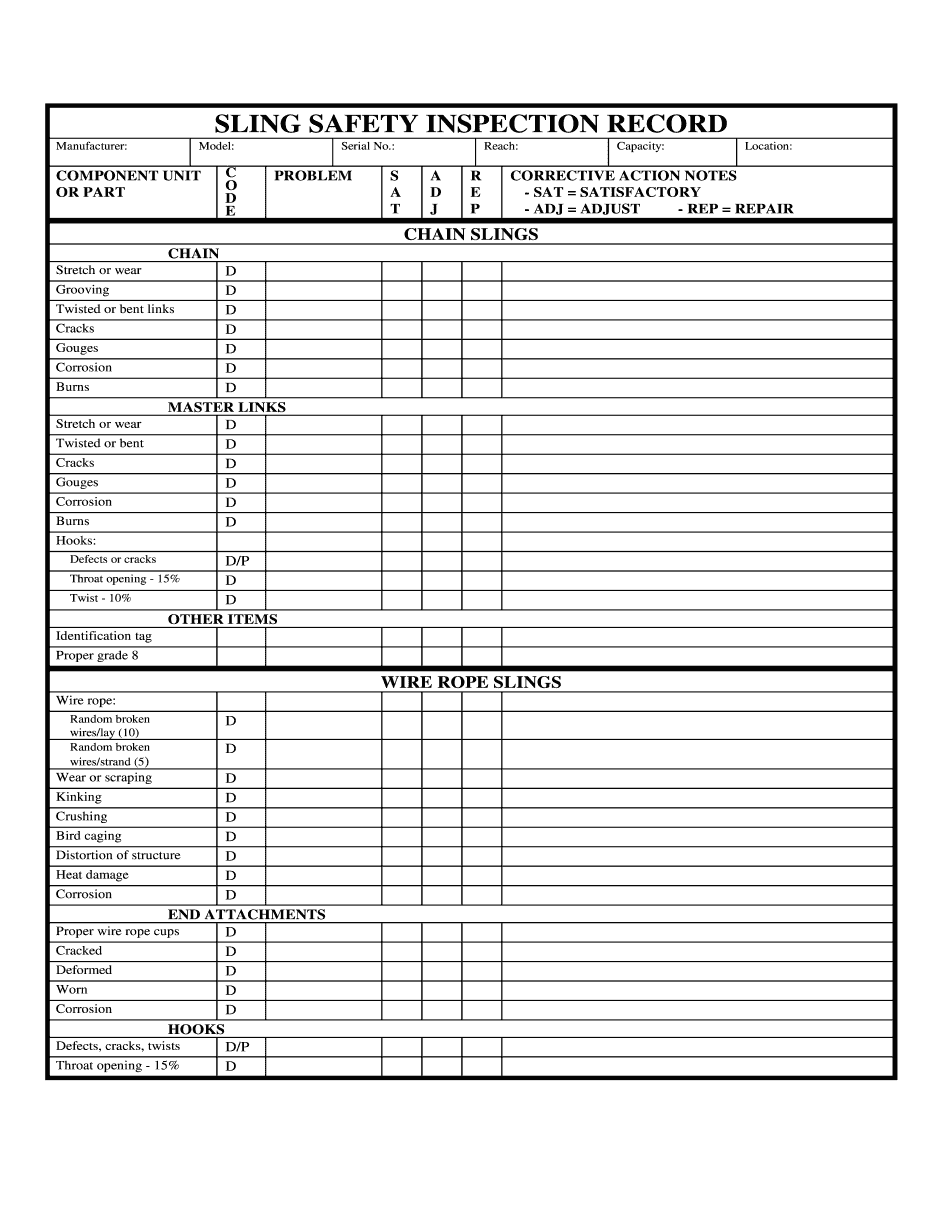

How to prepare Sling inspection Form Template

About Sling inspection Form Template

A Sling Inspection Form Template is a document that is used to systematically assess and record the condition and functionality of slings used in various industries. Slings are equipment used to lift and move heavy loads safely. The form template allows inspectors or designated personnel to perform a detailed examination of the slings, checking for any signs of damage, wear and tear, or other potential defects. The template typically includes sections to record the sling identification details, inspection date, and the inspector's name. It also provides a checklist or a series of questions related to various aspects of the sling, such as its material, load capacity, stitching, hooks, and other hardware. Inspectors can mark the checkboxes or fill in additional comments to note any observed issues or maintenance requirements. The form may also include sections for signatures and follow-up actions, such as repair recommendations or sling replacement. Various industries and organizations that utilize slings in their operations require the use of a sling inspection form. This includes construction companies, manufacturing plants, warehouses, logistics firms, oil and gas facilities, shipping yards, and many others. Following periodic sling inspections is essential to ensure the safe and efficient use of slings, preventing accidents, and complying with workplace safety regulations. The form template helps in standardizing the inspection process, maintaining proper records, and ensuring accountability for sling maintenance and replacement.

Online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Sling inspection Form Template, steer clear of blunders along with furnish it in a timely manner:

How to complete any Sling inspection Form Template online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our Assistance team.

- Place an electronic digital unique in your Sling inspection Form Template by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Sling inspection Form Template from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Sling inspection Form Template